Epdm Rubber BLOWING AGENT

Epdm Rubber BLOWING AGENT Specification

- Structural Formula

- C2H4N4O2

- Shelf Life

- 12 Months

- Melting Point

- >200C (decomposes)

- Taste

- Odorless

- EINECS No

- 204-650-8

- Boiling point

- Decomposes before boiling

- HS Code

- 29270090

- CAS No

- 123-77-3

- Color

- Light Yellow

- Molecular Formula

- C2H4N4O2

- Usage

- Used as a foaming/blowing agent in EPDM rubber and other polymeric products

- Smell

- No significant smell

- Water Cotent

- 0.20%

- Molecular Weight

- 116.08 g/mol

- Shape

- Fine Granule

- Storage

- Store in a cool, dry, well-ventilated area, away from heat and ignition sources

- Ph Level

- Neutral

- Appearance

- Powder

- Compatibility

- Compatible with most elastomers and polymers

- Application Industry

- Automotive, Construction, Footwear, Sealing Gaskets, Cables

- Residue on Sieve (150m)

- 0.5%

- Packaging

- 25 kg fiber drum or customized

- Gas Volume Generated

- Approx. 220-240 ml/g

- Purity

- 98%

- Decomposition Temperature

- ~200C

- Flammability

- Non-flammable

- Particle Size

- 10 m

- Grade Standard

- Industrial Grade

- Toxicity

- Non-toxic as per standard handling; handle with care

- Density

- About 1.8 g/cm

- Solubility

- Insoluble in water

Epdm Rubber BLOWING AGENT Trade Information

- Minimum Order Quantity

- 100 Kilogram

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, Eastern Europe, South America, Western Europe, Africa, Central America, Middle East, Asia

- Certifications

- ISO 9001:2015 Certified

About Epdm Rubber BLOWING AGENT

Adc 1224E For Epdm Rubber

This product is a specially designed for EPDM Rubber applications, profiles and other precision components. It can be used with various other EPDM plus other Rubbers like SBR ,NEOPRENE formulations with various processing techniques as per the requirements.

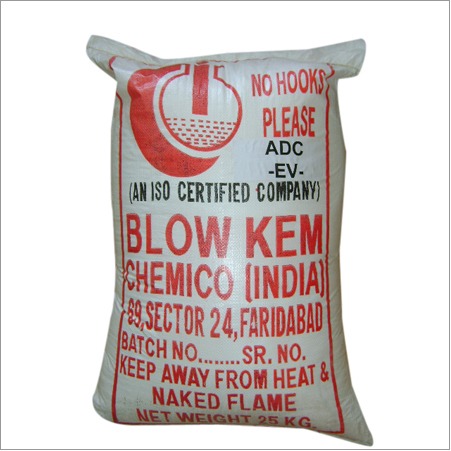

NAME : BLOWKEM ADC 1224 E

APPLICATION : FOR EPDM RUBBERS

Packing: 25 Kgs

Packing Type: Packed in HDPE polythene - lined woven bags with inner polythene bag

Optimized for Industrial Use

This EPDM rubber blowing agent is engineered for reliable performance in industrial settings, including automotive and construction sectors. Its fine particle size and decomposition properties allow consistent foaming, integral to producing high-quality rubber and polymer components such as seals, gaskets, and cable insulation.

Safe Handling and Storage

The blowing agent is classified as non-toxic and non-flammable, but it should still be handled with care. Store it in a cool, dry, well-ventilated area, away from heat sources and ignition points. Proper storage ensures its effectiveness and prevents decomposition, preserving its quality throughout the 12-month shelf life.

FAQs of Epdm Rubber BLOWING AGENT:

Q: How is the EPDM Rubber Blowing Agent used in manufacturing processes?

A: It is incorporated into EPDM rubber or compatible polymer mixes where, upon heating to its decomposition temperature (~200C), it releases gas to form a cellular structure, producing lightweight, flexible foam products.Q: What benefits does this blowing agent offer in end products?

A: The agent enables foam formation, resulting in reduced material weight, improved cushioning, thermal insulation, and flexibility, making it ideal for automotive, construction, and footwear applications.Q: When should the EPDM Rubber Blowing Agent be added during production?

A: It should be blended with the polymer or rubber compound prior to molding or extrusion. Activation occurs during heating, causing decomposition and gas generation within the material matrix.Q: Where can this blowing agent be effectively applied?

A: It is suited for industries producing automotive interiors, seals, gaskets, footwear soles, cable insulations, and construction profiles, wherever foam or lightweight materials are required.Q: What is the handling process required for this blowing agent?

A: Though non-toxic and non-flammable, it should be handled with gloves, in well-ventilated spaces, to avoid inhalation of fine powder. Spills should be cleaned immediately to maintain safety standards.Q: Why is particle size important in blowing agents for EPDM rubber?

A: A fine particle size (10 m) ensures uniform dispersion within the polymer matrix, leading to consistent cell structure and optimal physical properties in the finished foam product.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FOOTWEAR BLOWING AGENTS Category

ADC EV RUbber Chemical

Minimum Order Quantity : 100

Appearance : Powder

Smell : Other, Slight

Molecular Weight : 116.08 g/mol

Water Cotent : Max 0.3%

DNPT Blowing Agent

Price 125 INR

Minimum Order Quantity : 100

Appearance : Powder

Smell : Other, Odorless

Molecular Weight : 196.13 g/mol

Water Cotent : 0.3%

FOOTWEAR BLOWING AGENTS

Minimum Order Quantity : 100

Appearance : Powder

Smell : Other, Faint

Molecular Weight : 116.08 g/mol

Water Cotent : 0.3%

DNPT Blowkem 1000P

Minimum Order Quantity : 100

Appearance : Granular powder

Smell : Other, Neutral

Molecular Weight : 250.20 g/mol Grams (g)

Water Cotent : 0.3 %

|

CHEMICO (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry