ADC 140 AD

ADC 140 AD Specification

- Shelf Life

- 2 years under recommended storage conditions

- Product Type

- Chemical Compound

- HS Code

- 29270090

- Structural Formula

- O=C(NN=NN)NC=O

- Shape

- Granular/Powder

- Molecular Weight

- 116.08 g/mol

- Taste

- Odourless

- Usage

- Foaming agent for EVA, PE, PVC, rubber, and plastic products

- Density

- 1.65 Gram per cubic centimeter(g/cm3)

- Appearance

- Yellowish to orange powder

- Physical Form

- Powder

- Poisonous

- NO

- Smell

- Odourless

- Solubility

- Insoluble in water, soluble in dimethyl sulfoxide

- Ph Level

- Neutral

- Melting Point

- 225C (decomposes)

- Grade

- Industrial Grade

- Molecular Formula

- C2H4N4O2

- Application

- Used as a blowing agent in plastics, rubber, foam production, and shoe soles

- Purity

- >98%

ADC 140 AD Trade Information

- Minimum Order Quantity

- 100 Kilogram

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Eastern Europe, Western Europe, Africa, Central America, Australia, Middle East, South America, Asia, North America

- Certifications

- ISO 9001:2015 Certified

About ADC 140 AD

Blowkem ADC 140 AD

| Product | Particle Size | Gas | DT | Application |

| (microns) | (ml/gm) | (C) | ||

| Blowkem ADC 140 AD | - | - | - | Used in PVC Footwear with Injection moulding Mostly Used in Conjunction with our Blowkem - ADC - 5A006 G1/G2 and Many other application |

DT By Open Capillary Tube Method

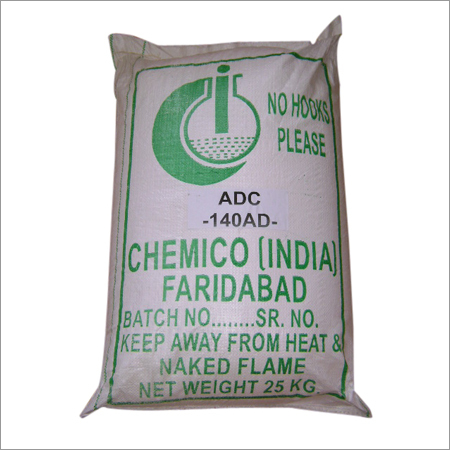

Packing: 25 Kgs

Packing Type: Packed in HDPE polythene - lined woven bags with inner polythene bag

Efficient Blowing Agent for Industrial Applications

ADC 140 AD is formulated to provide consistent and controlled foaming in polymer and rubber manufacturing. Its excellent gas-releasing properties make it an ideal choice for producing lightweight and durable products. With insolubility in water but solubility in dimethyl sulfoxide, it is versatile across various industrial processes.

Quality and Purity You Can Trust

With a purity of over 98% and stable chemical characteristics, ADC 140 AD ensures highly reliable results in foam production. Its odourless and non-toxic nature makes it safe to handle under recommended procedures, and its shelf life maintains product effectiveness for up to 24 months.

FAQs of ADC 140 AD:

Q: How is ADC 140 AD used in the production of foamed plastics and rubber?

A: ADC 140 AD is incorporated into polymer and rubber formulations as a blowing agent. When heated, it decomposes, releasing gases that produce a cellular structure, transforming solid materials into lightweight foamed products such as EVA, PE, PVC, and shoe soles.Q: What are the primary benefits of using ADC 140 AD in manufacturing?

A: ADC 140 AD provides uniform and controllable foaming, resulting in products with consistent density and enhanced physical properties. Its high purity ensures cleanliness, while its non-poisonous and odourless nature improves workplace safety.Q: When should ADC 140 AD be added to the production process?

A: ADC 140 AD should be mixed with other raw materials before or during the molding and extrusion processes. Heating during these stages initiates the decomposition necessary for foaming.Q: Where is ADC 140 AD mainly utilized?

A: ADC 140 AD is commonly used in plastics, rubber, and foam manufacturing industries, especially in the production of shoe soles, sports and yoga mats, and insulation materials.Q: What is the recommended storage method for ADC 140 AD to ensure maximum shelf life?

A: To maintain its properties and 2-year shelf life, store ADC 140 AD in a cool, dry, and well-ventilated area, away from sources of heat, moisture, and direct sunlight.Q: Is ADC 140 AD safe to handle during regular industrial operations?

A: Yes, ADC 140 AD is odourless, non-toxic, and considered safe to handle with standard industrial protective practices, as it does not emit hazardous fumes under normal conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Supplies Category

ADC 5A006 G2

Minimum Order Quantity : 100

Solubility : Insoluble in water, soluble in hydrocarbons

Smell : Other, Mild solvent odor

Grade : Technical Grade

Application : Other , Fuel injector and system cleaning for gasoline engines

Ph Level : 7.08.5

ADC 5A006 G1

Minimum Order Quantity : 100

Solubility : Soluble in water

Smell : Other, Odorless

Grade : Pharmaceutical Grade

Application : Other , Pharmaceuticals and drug formulation

Ph Level : Neutral

Chemtrax D Plastic Chemical

Minimum Order Quantity : 100

Solubility : Insoluble in water, soluble in organic solvents

Smell : Other, None

Grade : Industrial Grade

Application : Other , Used as an additive in the plastic manufacturing industry

Ph Level : Neutral (approx. 7)

Chemtrax L Rubber and Plastic Chemicals

Minimum Order Quantity : 100

Solubility : Dispersible in water

Smell : Other, Mild

Grade : Industrial

Application : Other , Rubber and plastic manufacturing industry

Ph Level : 7 (neutral)

|

CHEMICO (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry