DNPT Blowing Agent

DNPT Blowing Agent Specification

- Ph Level

- Neutral

- Usage

- Plastic and Rubber industries as a blowing agent

- Molecular Weight

- 196.13 g/mol

- Smell

- Odorless

- Structural Formula

- C2H8N6O4

- Color

- White

- Taste

- Tasteless

- HS Code

- 29270090

- Shape

- Granular

- Boiling point

- Decomposes before boiling

- Molecular Formula

- C2H8N6O4

- Water Cotent

- 0.3%

- Appearance

- Powder

- Melting Point

- 93C 96C

- Shelf Life

- 24 Months

DNPT Blowing Agent Trade Information

- Minimum Order Quantity

- 100 Kilogram

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Certifications

- ISO 9001:2015 Certified

About DNPT Blowing Agent

| Product | Gas | DT | Application |

| (ml/gm) | (C) |

||

|

BLOWING AGENT FOR RUBBER- Blowkem206

|

- | - |

DNPT (Dinitrosopentamethylenetetramine) is blowing agent for natural and synthetic rubber. It is primarily used in rubber slippers and also in lightweight shoe soles. It is also used with Styrene butadiene rubber to manufacture pipes and hoses. |

DT By Open Capillary Tube Method

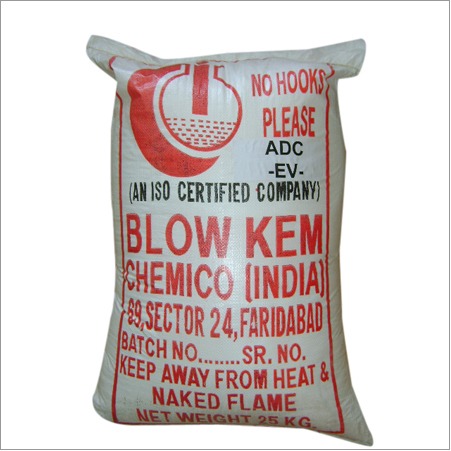

Packing: 25 Kgs

Packing Type: Packed in HDPE polythene - lined woven bags with inner polythene bag

Applications in Plastics and Rubber Industries

DNPT Blowing Agent is primarily utilized in the manufacturing of plastic and rubber materials, where it facilitates the expansion of polymers to create foamed products. Its stable granular form ensures consistent results in applications such as insulation, cushioning, and packaging solutions. DNPT is favored for its efficiency and reliability during high-volume production.

Key Technical Properties and Handling

This blowing agent is white, tasteless, and odorless, offering a safe and clean approach to foaming processes. With a melting point of 93C96C and low water content, DNPT is easy to handle and store. The product should be kept sealed in a cool, dry environment to preserve its 24-month shelf life. For safety and best performance, follow standard industrial protocols during handling.

FAQs of DNPT Blowing Agent:

Q: How is DNPT Blowing Agent used in the plastics and rubber industries?

A: DNPT Blowing Agent is incorporated into polymer mixtures during the manufacturing process. Upon heating, it decomposes and releases gas, which forms bubbles that create a lightweight, foamed structure in the final plastic or rubber product.Q: What are the benefits of using DNPT over other blowing agents?

A: DNPT offers a neutral pH, consistent granular form, and low water content, contributing to stable processing and superior foam quality. It is also odorless and tasteless, making it ideal for applications requiring contamination-free results.Q: When should DNPT Blowing Agent be added during the production process?

A: DNPT is typically introduced during the mixing or compounding stage, before the material is subjected to heat. It is essential to add it before the formation or shaping process for effective foaming action.Q: Where can DNPT Blowing Agent be sourced from?

A: DNPT Blowing Agent is available from exporters, manufacturers, and suppliers in India. It is traded under the HS Code 29270090, with global shipping options for industrial clients.Q: What is the shelf life and ideal storage conditions for DNPT?

A: The shelf life of DNPT Blowing Agent is 24 months when stored in a tightly sealed container, kept in a cool, dry place away from direct sunlight and moisture to maintain stability and performance.Q: What is the process of decomposition for DNPT Blowing Agent?

A: Upon heating to its melting point (93C96C), DNPT decomposes, producing gases that create cellular structures in polymers. It does not boil but breaks down to facilitate foaming in plastics and rubber.Q: Is DNPT Blowing Agent safe to handle?

A: Yes, DNPT is tasteless, odorless, and neutral in pH, making it relatively safe when handled with standard industrial precautions such as protective gloves, eyewear, and adequate ventilation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FOOTWEAR BLOWING AGENTS Category

Epdm Rubber BLOWING AGENT

Minimum Order Quantity : 100

Usage : Used as a foaming/blowing agent in EPDM rubber and other polymeric products

Molecular Weight : 116.08 g/mol

Structural Formula : C2H4N4O2

HS Code : 29270090

Taste : Odorless

ADC EV RUbber Chemical

Minimum Order Quantity : 100

Usage : Blowing agent for EVA, PVC, Rubber, PE foaming

Molecular Weight : 116.08 g/mol

Structural Formula : C2H4N4O2

HS Code : 29270090

Taste : Odorless

FOOTWEAR BLOWING AGENTS

Minimum Order Quantity : 100

Usage : Used as blowing agent in manufacturing of EVA/ PVC/ Rubber footwear

Molecular Weight : 116.08 g/mol

Structural Formula : C2H4N4O2

HS Code : 29270090

Taste : Odorless

DNPT Blowkem 1000P

Minimum Order Quantity : 100

Usage : Chemical blowing agent for EVA, Rubber, Plastic, PVC, LDPE

Molecular Weight : 250.20 g/mol Grams (g)

Structural Formula : C9H10N4O4

HS Code : 29270090

Taste : Odorless

|

CHEMICO (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry