DNPT Blowkem 1000P

DNPT Blowkem 1000P Specification

- Storage

- Store in cool, dry place in tightly sealed containers

- Boiling point

- No boiling, decomposes above melting point

- Shape

- Spherical granules

- HS Code

- 29270090

- Color

- White to pale yellow

- Molecular Formula

- C9H10N4O4

- Water Cotent

- 0.3 %

- Usage

- Chemical blowing agent for EVA, Rubber, Plastic, PVC, LDPE

- Shelf Life

- 2 years Years

- Appearance

- Granular powder

- Structural Formula

- C9H10N4O4

- Smell

- Neutral

- Molecular Weight

- 250.20 g/mol Grams (g)

- Taste

- Odorless

DNPT Blowkem 1000P Trade Information

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia, North America

- Certifications

- ISO 9001:2015 Certified

About DNPT Blowkem 1000P

BLOWING AGENT FOR RUBBER- Blowkem 1000P

| Product | Gas | DT | Application |

| (ml/gm) | (C) |

||

| BLOWING AGENT FOR RUBBER- Blowkem 1000P | - | - |

DNPT (Dinitrosopentamethylenetetramine) is blowing agent for natural and synthetic rubber. It is primarily used in rubber slippers and also in lightweight shoe soles. It is also used with Styrene butadiene rubber to manufacture pipes and hoses. |

DT By Open Capillary Tube Method

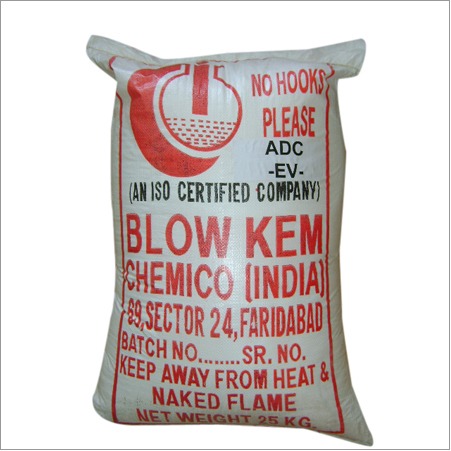

Packing: 25 Kgs

Packing Type: Packed in HDPE polythene - lined woven bags with inner polythene bag

Efficient Blowing Agent for Diverse Applications

DNPT Blowkem 1000P serves as an effective chemical blowing agent suited for EVA, rubber, plastic, PVC, and LDPE. Thanks to its controlled decomposition above the melting point, it ensures consistent cellular structures in foamed products, contributing to lightweight and durable finished goods. Its high purity and granule consistency make it a top choice for manufacturers seeking reliability and versatility across various industrial applications.

Safe Storage and Longevity

To preserve the quality and performance of DNPT Blowkem 1000P, keep it in cool, dry places within tightly sealed containers. This helps prevent moisture contamination and degradation, ensuring the product maintains its physical properties. Under proper storage conditions, DNPT Blowkem 1000P retains its efficacy for up to two years.

FAQs of DNPT Blowkem 1000P:

Q: How should DNPT Blowkem 1000P be stored to maintain its effectiveness?

A: DNPT Blowkem 1000P should be stored in a cool, dry environment inside tightly sealed containers. Storing it this way helps prevent moisture uptake and maintains its quality throughout its two-year shelf life.Q: What are the recommended applications for DNPT Blowkem 1000P?

A: This chemical blowing agent is designed for use in the production of EVA, rubber, plastic, PVC, and LDPE products. It is extensively utilized to create lightweight, foamed materials with improved insulation and cushioning properties.Q: When does DNPT Blowkem 1000P decompose during processing?

A: DNPT Blowkem 1000P decomposes above its melting point rather than boiling, producing gas that enables foaming during the heating process in manufacturing. This controlled decomposition results in uniform cell formation in final products.Q: Where is DNPT Blowkem 1000P manufactured and exported from?

A: This blowing agent is manufactured, supplied, and exported from India, adhering to international standards to serve global markets in various industries.Q: What is the process for using DNPT Blowkem 1000P in manufacturing?

A: DNPT Blowkem 1000P is mixed with polymers such as EVA, rubber, or PVC before being processed at elevated temperatures. As the temperature rises above its decomposition point, it releases gas that expands the polymer into a foamed structure.Q: What benefits does DNPT Blowkem 1000P offer to manufacturers?

A: DNPT Blowkem 1000P delivers consistent foaming action, resulting in lightweight, uniformly expanded products. Its neutral odor, stability, and low moisture content ensure high-quality output and ease of handling during processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FOOTWEAR BLOWING AGENTS Category

Epdm Rubber BLOWING AGENT

Minimum Order Quantity : 100

Color : Other, Light Yellow

HS Code : 29270090

Molecular Weight : 116.08 g/mol

Smell : Other, No significant smell

ADC EV RUbber Chemical

Minimum Order Quantity : 100

Color : Other, White or light yellow

HS Code : 29270090

Molecular Weight : 116.08 g/mol

Smell : Other, Slight

DNPT Blowing Agent

Price 125 INR

Minimum Order Quantity : 100

Color : White

HS Code : 29270090

Molecular Weight : 196.13 g/mol

Smell : Other, Odorless

FOOTWEAR BLOWING AGENTS

Minimum Order Quantity : 100

Color : Other, Light Yellow

HS Code : 29270090

Molecular Weight : 116.08 g/mol

Smell : Other, Faint

|

CHEMICO (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry