FOOTWEAR BLOWING AGENTS

FOOTWEAR BLOWING AGENTS Specification

- Molecular Weight

- 116.08 g/mol

- Storage

- Cool, dry place, away from direct sunlight

- Taste

- Odorless

- Smell

- Faint

- Usage

- Used as blowing agent in manufacturing of EVA/ PVC/ Rubber footwear

- Color

- Light Yellow

- Appearance

- Powder

- Water Cotent

- 0.3%

- Melting Point

- >190C (Decomposes before melting)

- Shape

- Fine Granular

- Shelf Life

- 2 Years

- Structural Formula

- C2H4N4O2

- Molecular Formula

- C2H4N4O2

- HS Code

- 29270090

FOOTWEAR BLOWING AGENTS Trade Information

- Minimum Order Quantity

- 100 Kilogram

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Certifications

- ISO 9001:2015 Certified

About FOOTWEAR BLOWING AGENTS

We are manufacturing various grades of Blowing Agents for the Footwear Industry depending on the type of polymers used.

Some of our products Especially for Footwear are;

ADC EV

ADC PT

ADCL 5005

ADC 140 AD & ADC 5A006

ADC TWO COMPONENT

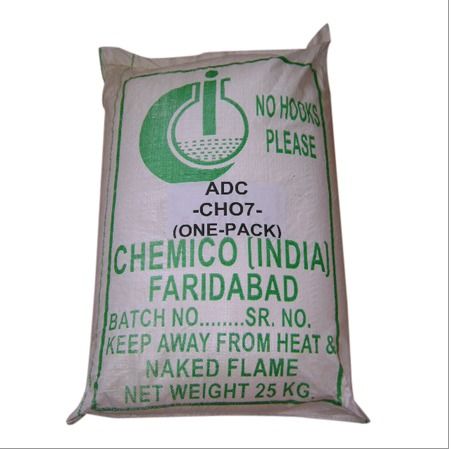

ADC ONE PACK

DNPT ( FOR HAWAI SLIPPERS AND OTHER RUBBER ITEMS)

PRODUCT APPLICATION

- EVA Slippers, Hawai Chappals, Canvas Shoes, etc.

- PVC Shoe Soles

- LDPE

- Natural and Synthetic Rubber Applications

- Rubber Foams

- Rubber Linings for Doors and Windows

- Layered Water Tanks

- Precision Rubber Components

- Coaxial Cables

- PE Extrusion

- Transmission Belts

- Tyre

- Pipes and Hoses.

Superior Quality and Performance

Our FOOTWEAR BLOWING AGENTS are expertly engineered for footwear manufacturing, providing excellent foam structure and improved material resilience. The fine granular appearance aids rapid dispersion within EVA, PVC, and rubber compounds, resulting in uniform cellular formation during processing. The agents low moisture content ensures consistency and long shelf life, making it a trusted choice for manufacturers and suppliers.

Secure Packaging and Storage

Each batch is packaged to preserve the agents integrity, maintaining optimal water content and minimizing contamination. For best results, store in a cool, dry location, shielded from direct sunlight. These conditions help sustain product efficacy and extend shelf life to two years, maximizing usability for exporters and manufacturers.

FAQs of FOOTWEAR BLOWING AGENTS:

Q: How are FOOTWEAR BLOWING AGENTS used in footwear manufacturing?

A: FOOTWEAR BLOWING AGENTS are incorporated into EVA, PVC, or rubber mixtures during the production of footwear soles. When heated, they decompose above 190C, releasing gas that creates foam structure, providing cushioning and reducing weight.Q: What is the benefit of using blowing agents in EVA/PVC/rubber footwear?

A: The main advantage of using blowing agents is the formation of lightweight, comfortable, and resilient foam soles. They improve shock absorption and reduce overall material consumption, enhancing the quality and comfort of the footwear.Q: When should the blowing agent be added during the manufacturing process?

A: The blowing agent is typically mixed with the polymer compound prior to molding and heating. This ensures even distribution and allows optimal cellular structure to form during the thermal decomposition stage.Q: Where should the blowing agent be stored to maintain its quality?

A: For best results, the blowing agent should be kept in a cool, dry environment, away from direct sunlight. Proper storage extends shelf life and protects the product from moisture, maintaining its effectiveness.Q: What is the shelf life of FOOTWEAR BLOWING AGENTS and how do you ensure product stability?

A: The shelf life of the product is two years when stored correctly. Stability is ensured by maintaining water content at or below 0.3% and shipping the product in secure, moisture-resistant packaging.Q: What process does the agent undergo during footwear production?

A: During production, the agent decomposes before melting, releasing gases that create fine cellular structures in the footwear sole material. This process yields a lightweight, cushioned result that enhances product performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FOOTWEAR BLOWING AGENTS Category

ADC EV RUbber Chemical

Minimum Order Quantity : 100

Molecular Weight : 116.08 g/mol

Usage : Blowing agent for EVA, PVC, Rubber, PE foaming

Color : Other, White or light yellow

Taste : Odorless

Epdm Rubber BLOWING AGENT

Minimum Order Quantity : 100

Molecular Weight : 116.08 g/mol

Usage : Used as a foaming/blowing agent in EPDM rubber and other polymeric products

Color : Other, Light Yellow

Taste : Odorless

DNPT Blowing Agent

Price 125 INR

Minimum Order Quantity : 100

Molecular Weight : 196.13 g/mol

Usage : Plastic and Rubber industries as a blowing agent

Color : White

Taste : Other , Tasteless

DNPT Blowkem 1000P

Minimum Order Quantity : 100

Molecular Weight : 250.20 g/mol Grams (g)

Usage : Chemical blowing agent for EVA, Rubber, Plastic, PVC, LDPE

Color : Other, White to pale yellow

Taste : Odorless

|

CHEMICO (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry